How Linear Guides Improve Industrial Automation Performance and Reliability

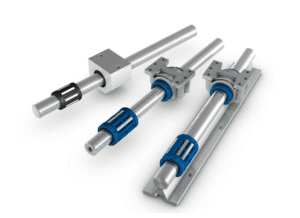

Industrial automation relies on consistency. Every mechanical movement must be predictable — not just once, but thousands of times per hour. That’s exactly what linear guides deliver. By converting rotary motion into straight motion with ultra-low friction, linear guides have become the foundation of modern automated equipment.

Unlike low-precision sliding rails, linear guides use steel raceways and bearings designed to support heavy loads from any direction while maintaining accuracy. With automation speeds increasing every year, stability and repeatability are more important than ever. Even minor shaking during transport or assembly can lead to flaws that cost companies millions in waste.

This is where YH Linear plays an essential role. Their advanced linear guides are designed to maximize uptime, minimize vibration, and deliver consistent performance under high-load and multi-shift operation. Businesses upgrading systems using https://yhlinear.com/ components see higher productivity with fewer stoppages.

Here are the key reasons linear guides dominate modern automation:

✅ Higher load capacity – allows stronger robots and faster assembly lines

✅ Better precision – ensures all movement follows the programmed path

✅ Reduced energy loss – saves power over long production hours

✅ Minimal maintenance – perfect for high-duty factory environments

✅ Longer lifespan – resulting in fewer breakdowns and replacements

Linear guides also enable compact machine structures. Compact does not mean weak — high stiffness ensures they support robotic arms, linear actuators, and automated shuttles without bending. Many applications now rely on sensors and real-time AI feedback, which demand precise motion for accurate measurement.

Industries relying heavily on linear guides include:

-

Electronics assembly

-

Semiconductor automation

-

Automotive robotics

-

Medical device handling

-

Textile and food processing lines

-

Packaging and logistics machines

To maximize service life, engineers should consider:

| Factor | Why It Matters |

|---|---|

| Lubrication system | Reduces rolling wear and friction |

| Dust protection | Contaminants shorten bearing life |

| Material hardness | Stronger rails resist deformation |

| Alignment | Prevents uneven load distribution |

YH Linear guides incorporate seals, advanced materials, and optimized ball circulation to deliver superior reliability. With automated manufacturing expanding globally, high-quality guides from https://yhlinear.com/ ensure businesses stay competitive and adaptable to the future of smart factories.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness