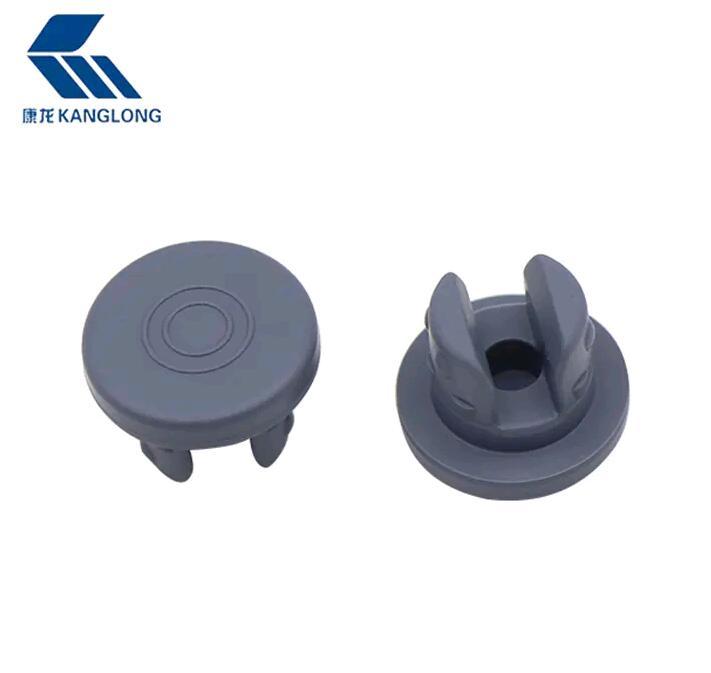

Sealing Solutions: Medical Butyl Rubber Stoppers for Pharmaceutical Use

In the pharmaceutical and medical industries, ensuring the safety, stability, and sterility of injectable medications is critical. One essential component in this process is the stopper used to seal vials containing medicines, vaccines, and biological products. Among various options, medical lyophilization freeze-dried butyl rubber stoppers have become widely adopted due to their unique properties and suitability for freeze-dried drug formulations.

Medical lyophilization freeze-dried butyl rubber stoppers are specially designed rubber seals used to close vials that contain freeze-dried (lyophilized) pharmaceuticals. Lyophilization is a freeze-drying process used to preserve sensitive drugs, vaccines, and biological samples by removing moisture under low temperature and pressure. This method increases the shelf life and stability of medicines that would otherwise degrade in liquid form.

Butyl rubber, a synthetic elastomer made from isobutylene with small amounts of isoprene, is the material of choice for these stoppers because of its excellent chemical inertness and sealing properties. These stoppers are manufactured under strict medical-grade standards and designed to maintain vial integrity throughout the lyophilization process, storage, and eventual drug administration.

One of the most important features of butyl rubber stoppers is their chemical resistance. Butyl rubber exhibits excellent inertness, meaning it does not react chemically with the contents of the vial or the external environment. This property prevents contamination and ensures that the medication inside remains pure and effective.

Moreover, butyl rubber resists interaction with solvents, moisture, and gases, helping maintain a stable internal atmosphere inside the vial, which is critical for freeze-dried drugs.

https://www.klstopper.com/product/pharmaceutical-rubber-stopper/lyophilization-freezedried-butyl-rubber-stoppers.html

Excellent sealing performance

Replacement of barrier rubber stoppers

Provides special chlorobutyl rubber formula for good compatibility

With pharmaceuticals Special treatment process and the most stringent process control ensure the cleanliness of the rubber stopper

Microbiological testing is to ensure the safety of rubber stoppers

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness