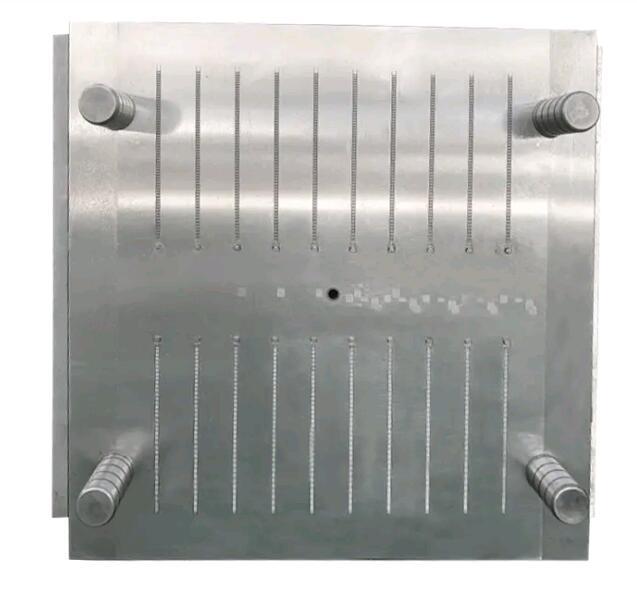

Cable Management Solutions: Cable Tie Moulds for Organized Cabling

A cable tie mould is an essential tool used in the production of plastic cable ties. These moulds enable the mass production of cable ties, which are commonly used for bundling and securing wires, cables, and other items in various industries.

The primary use of a cable tie mould is in injection moulding, a process where molten plastic is injected into the mould cavity. The mould defines the exact shape, size, and design of the cable tie, ensuring consistent quality and precise dimensions. This process allows for efficient high-volume production, making cable ties readily available for a wide range of applications.

One important benefit of using a cable tie mould is production efficiency. Manufacturers can produce large quantities of cable ties in a relatively short time, which helps meet market demand. The mould can be designed with multiple cavities, allowing for the simultaneous production of several cable ties per cycle, further increasing output.

Another key function of the mould is ensuring product quality. A well-designed mould produces cable ties with strong locking mechanisms and smooth surfaces, which are important for durability and ease of use. Consistent production quality also ensures that the cable ties meet safety and performance standards required in industries such as automotive, construction, and electronics.

Cable tie moulds also offer flexibility in design. They can be customized to produce cable ties of various lengths, widths, and colours to suit different needs. This versatility allows manufacturers to supply products for a wide range of applications, from light-duty household use to heavy-duty industrial purposes.

https://www.automobiletiemould.com/product/pp-seal-cable-tie-mold/threeplate-mold-split-cable-tie-mold-plastic-pp-seal-logistics-sign-cable-tie-tag.html

The PP Seal Cable Tie Mold features a three-plate mold split system, which is an advanced design for the production of plastic cable ties. This system allows for efficient and precise molding operations, reducing production time and maintenance costs.

The mold is designed to produce cable ties made from polypropylene (PP), a material known for its strength, durability, and resistance to chemicals. The choice of PP ensures that the cable ties produced by the PP Seal Cable Tie Mold offer performance and long-term stability.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness