Creative Optimization Solutions for CNC Machining Costs

I. Innovation in Material Selection

Exploration of Alternative Materials

Actively research new materials that can replace traditional ones. For example, in the machining of some parts where extremely high strength is not required, high-performance engineering plastics can be used instead of metal materials. Take polyetheretherketone (PEEK) plastic as an example. It has good mechanical properties and chemical stability, but its density is much lower than that of metal. It can significantly reduce the weight of parts. Moreover, during the machining process, the cutting force is small, which can reduce the wear of cutting tools, shorten the machining time, and the comprehensive cost may be lower than that of metal.

Utilization of Recycled Materials

Cooperate with professional recycling institutions to purchase processed recycled metal materials. For some parts that do not have high requirements for appearance but have certain standards for mechanical properties, materials such as recycled aluminum alloy can be used. The prices of these materials are usually lower than those of virgin materials. After undergoing strict inspections to ensure that the quality meets the standards, they can be put into production. This not only reduces the material cost but also conforms to the concept of environmental protection and enhances the corporate image.

II. Optimization of Machining Processes

Tool Path Planning

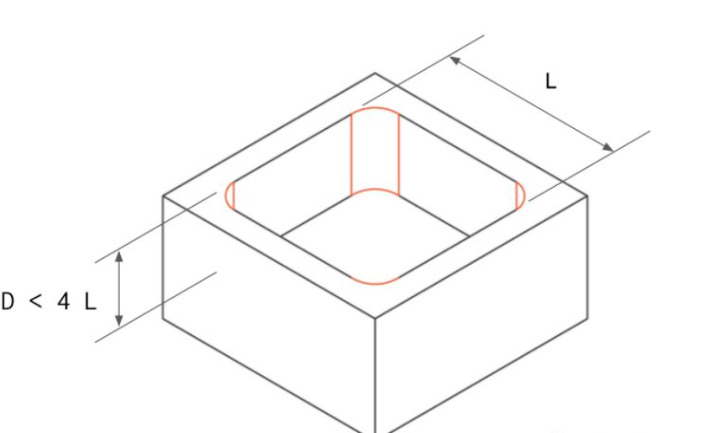

Use advanced CAM software to conduct in-depth analysis of the shape and machining requirements of parts, and generate more efficient tool paths. By reducing the idle travel of the tool and optimizing the cutting sequence, unnecessary cutting actions can be avoided. For instance, when machining parts with complex cavities, adopting the spiral tool entry method instead of the traditional vertical tool entry method can make the tool force more uniform, reduce tool wear, improve machining efficiency, and lower the cost of machining time.

Combination of High-Speed Cutting and Minimum Quantity Lubrication (MQL)

Introduce high-speed cutting technology. While increasing the cutting speed, it is accompanied by a Minimum Quantity Lubrication (MQL) system. The MQL system precisely sprays a small amount of lubricant into the cutting area. It can effectively reduce the cutting temperature, decrease tool wear, and also reduce the usage amount of cutting fluid and its subsequent treatment cost. For example, when machining aluminum alloy parts, high-speed cutting combined with MQL can increase the machining efficiency by more than 30% and reduce the cutting fluid cost by about 70%.

III. Innovation in Production Management

Order Integration Strategy

Establish a customer order database and conduct real-time analysis of orders. When receiving multiple small-batch orders, if the machining processes of the parts are similar, these orders can be integrated into a large order for production. By preparing raw materials at one time, adjusting equipment parameters, etc., the frequent debugging of equipment and the time for mold changing can be reduced, the equipment utilization rate can be improved, and the machining cost per unit part can be lowered. For example, by integrating the orders for multiple small aluminum alloy brackets for production, the machining cost per piece can be reduced by about 15%.

Remote Monitoring and Predictive Maintenance

Install sensors on CNC equipment to achieve remote monitoring of the equipment's operating status. Through data analysis, potential faults of the equipment can be predicted in advance, and maintenance can be arranged in a timely manner to avoid production interruptions and additional maintenance costs caused by sudden equipment failures. For example, through predictive maintenance, the equipment downtime can be reduced by 40%, and at the same time, the service life of the equipment can be extended, and the equipment depreciation cost allocated to each part can be correspondingly reduced.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness