Linear Bearings in Clean-Room Robotics: Why Sub-Class 1 ISO Performance Demands More

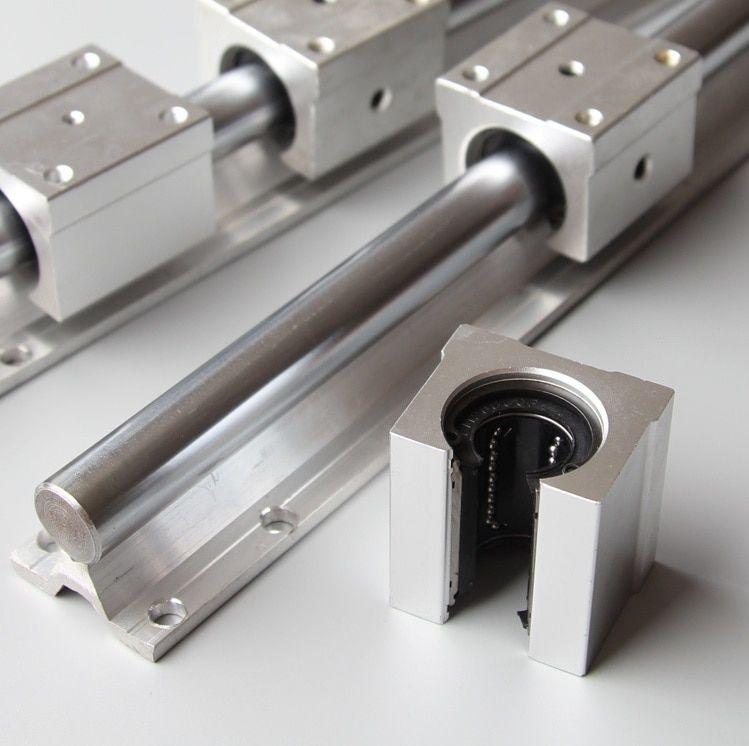

When a wafer-handling robot glides across a semiconductor clean-room, the linear bearings hidden inside its forearm are expected to deliver repeatability measured in single-digit microns—while generating fewer than ten particles larger than 0.1 µm per meter of travel. Achieving this contradiction between mechanical contact and near-zero contamination is no longer a laboratory curiosity; it is a production prerequisite for 3 nm process nodes. Over the past decade, the industry has learned that traditional recirculating-ball linear bearings, although precise, can shed stainless-steel micro-flakes every time the ball chain crosses the end-cap seam. The solution has been a multi-disciplinary rethink of raceway geometry, surface finish, lubrication chemistry, and even the bearing’s magnetic signature.

First, raceway geometry. A conventional Gothic-arch profile concentrates Hertzian stress at two tiny contact ellipses, generating sub-surface fatigue that eventually spalls. Clean-room-grade linear bearings now use a four-point-contact circular arc that spreads the load over a 30 % larger ellipse area. Finite-element analysis shows a 22 % reduction in maximum shear stress, which translates into an order-of-magnitude drop in particle generation after one billion cycles. The challenge, however, is maintaining preload as the contact angle changes. Manufacturers laser-grind the raceways in a single chucking operation to guarantee roundness within 0.8 µm over the full 400 mm length, then match ball chains in 1 µm diameter increments so that axial play stays below 2 µm throughout the lifetime of the bearing.

Second, surface finish. While Ra 0.1 µm was once considered “mirror,” clean-room bearings now demand Ra 0.02 µm with defined plateau honing to retain lubricant without harboring trapped slurry. Achieving this finish on martensitic stainless steel requires a three-step sequence: micro-blasting with 5 µm alumina to remove re-cast layers, electrolytic polishing to round micro-peaks, and finally magnetorheological finishing that aligns grain boundaries parallel to the ball path. The cumulative surface stress drops by 35 %, delaying the onset of fatigue spallation that would otherwise seed particle bursts.

Third, lubrication. Traditional lithium-soap greases are too viscous for sub-Class 1 environments; they trap airborne ammonia and outgas hydrocarbons that contaminate EUV optics. Clean-room linear bearings now employ perfluoropolyether (PFPE) oils thickened with micronized PTFE. These compounds have vapor pressures below 10⁻¹² Torr at 25 °C and are certified to SEMI F57, yet still maintain a 0.12 µm elastohydrodynamic film at 1 m s⁻¹. Re-lubrication is handled through a 0.3 mm nickel bellows integrated into the carriage, metering 0.5 µL every 50 km of travel—enough for two years of 24/7 duty without opening the chamber.

Magnetic cleanliness is an emerging constraint. EUV steppers use magnetic levitation stages that can be perturbed by ferrous debris. Linear bearings now specify residual magnetization below 2 nT at 1 mm distance. This is achieved by vacuum-melting 440C stainless steel in an argon-oxygen decarburization furnace, followed by rapid quench and triple tempering to eliminate retained austenite. A final demagnetization pulse aligns domain walls randomly, ensuring that the bearing neither attracts nor sheds ferromagnetic particles.

Validation is performed in a Class 0.1 mini-environment where a laser particle counter continuously samples air 3 mm above the bearing. Current production batches must remain below 3 particles m⁻³ (>0.1 µm) over 10 million cycles at 2 m s⁻² acceleration before release. The payoff: fabs running these bearings report a 40 % reduction in unscheduled chamber cleans, translating into an extra 12,000 wafer starts per year on a single lithography track.

The next frontier is predictive maintenance via acoustic emission. By embedding a MEMS microphone inside the end cap, engineers can detect the ultrasonic signature of incipient spallation 200 hours before particle counts rise above baseline. Machine-learning models trained on 50 billion cycles now predict remaining useful life within ±3 %, allowing fabs to swap bearings during scheduled downtime rather than during a critical EUV lot.

Site içinde arama yapın

Kategoriler

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Battlefield 6 Weapon Proficiency Guide for All Classes

In most modern FPS games, levelling up a weapon usually means unlocking a few attachments or...

B2B Influencer Marketing Agency Market Set for Significant Growth by 2025 - Key Players, Trends, and Future Outlook

B2B Influencer Marketing Agency market Size, Status, and Forecast for the 2025-2034. In-depth...

Durability and Efficiency at the Core of the Fire Extinguisher Market

The fire extinguisher market has transitioned from being an industrial-centric necessity to...

Interlining Technology Transforming Garment Structure And Comfort By Interlining-Factory

In contemporary apparel production, the hidden layer inside a garment increasingly dictates how a...

Reliable Lithium-Ion Impact Wrenches for Tough Jobs

When it comes to tough jobs, the KimoPower Lithium-Ion Impact Wrench is the tool you need to...