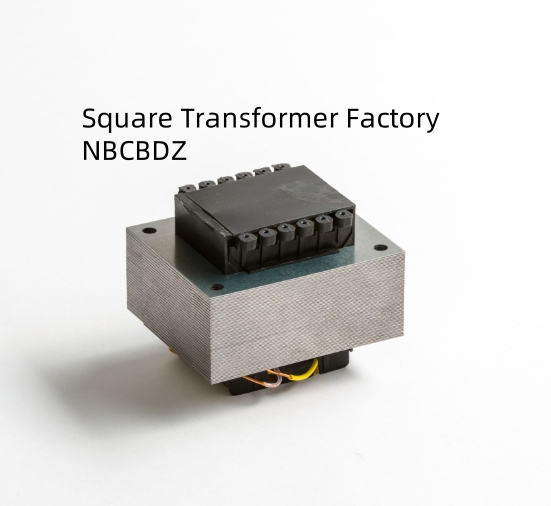

Why Nbcbdz Square Transformer Factory addresses client size requests

Square Transformer Factory is an important resource for businesses that require customized electrical components. Many industries, from automation to power distribution, face projects where standard sizes do not fit their technical requirements. Understanding how a factory handles these custom requests allows buyers to make informed sourcing decisions.

Custom size requests usually start with an evaluation of the project specifications. Buyers often provide detailed drawings, voltage ratings, and dimensional needs. The factory then reviews whether the production lines can accommodate these requirements without affecting quality or performance. Careful planning at this stage helps avoid unnecessary revisions later in the process.

One of the main considerations is material selection. Transformer efficiency and durability depend on the core, windings, and insulation materials used. When dimensions change, these materials must be adjusted to ensure the final product performs as expected. This step is particularly important in industries where safety standards and compliance play a major role.

Communication between buyer and manufacturer is another factor. A reliable partner like Nbcbdz ensures that every adjustment is clearly explained before production begins. This involves reviewing technical drawings, confirming tolerance levels, and aligning delivery schedules. Such cooperation reduces risk and builds trust, which is especially important when sourcing for automation or large-scale industrial systems.

Another element to consider is testing. Custom transformers require additional performance checks to confirm that the modified size still maintains stable operation. Factories that offer in-house testing save buyers time and provide assurance that the transformer will work in its intended environment. This prevents costly downtime once the equipment is installed.

Flexibility in production is also valuable. Not every order requires the same level of customization. Some buyers may need slight changes in dimensions, while others require significant modifications. The ability to scale production for both small and large requests gives buyers confidence that their needs can be met consistently.

Logistics play a crucial role as well. When a transformer has non-standard dimensions, packaging and transportation must be carefully arranged to prevent damage during shipment. Buyers are encouraged to ask about how these challenges are managed, especially when shipping internationally.

Procurement strategies should also take long-term requirements into account. Ordering a small batch of customized units may serve immediate needs, but planning ahead for repeat orders can help maintain continuity. Factories that maintain clear records of specifications simplify this process and shorten future lead times.

Making decisions in this area is not only about size adjustments but about securing a manufacturing partner that understands the entire process. From consultation to production, communication and testing, Nbcbdz offers structured solutions that align with industrial demands.

By focusing on specifications, testing, and communication, buyers can approach custom sourcing with confidence. With proper planning and coordination, challenges such as non-standard sizes can be turned into opportunities for better system design. To learn more about cooperation opportunities, visit https://www.nbcbdz.com/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness