Advantages of Automotive Injection Moulding

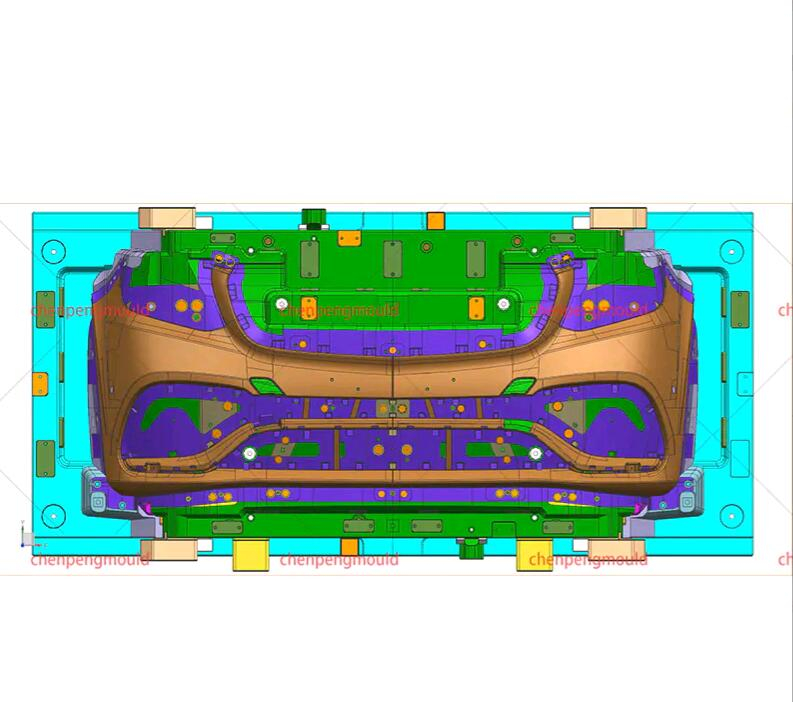

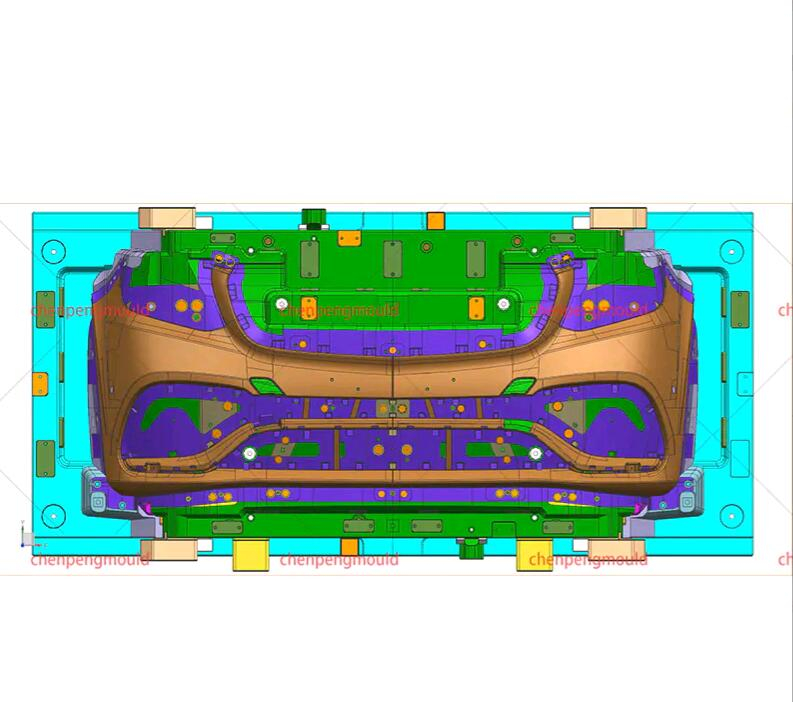

Automotive injection moulding has become a cornerstone of modern vehicle manufacturing because it combines efficiency, precision, and material flexibility. This process involves injecting molten plastic into a mould to form components that meet both functional and design requirements. Its advantages explain why it is widely applied in producing parts such as bumpers, dashboards, and interior trims.

One significant advantage is precision. Automotive components must fit together seamlessly while meeting safety and performance standards. Injection moulding ensures consistent dimensions and surface quality, allowing for reliable assembly and reduced post-processing. This capability is particularly valuable for complex geometries that would be difficult to achieve with alternative methods.

Efficiency is another key benefit. Injection moulding supports high-volume production with relatively short cycle times, making it cost-effective for manufacturers. The process also allows for the integration of features—such as clips, ribs, or mounting points—directly into the part, which reduces the need for additional assembly steps.

Material versatility further enhances its value. A wide range of thermoplastics can be used, enabling manufacturers to balance durability, weight reduction, and aesthetic appeal. Many of these materials are recyclable, aligning with sustainability goals in the automotive sector.

Automotive injection moulding offers clear advantages in precision, production efficiency, and material adaptability. These strengths have made it a practical and reliable choice for producing the diverse components required in modern vehicles.

https://www.bumpermould.net/product/bumper-mould/no-flash-mercedesbenz-gls-maybach-front-bumper-mould.html

Why choose us?

Experience: We have had strong expertise in designing and developing automotive injection molds since 2000. Our company has developed 1000 bumper molds, including Volkswagen, Audi, Mercedes, BMW, Toyota, Ford, Skoda, etc. Moreover, we also developed higcarsbumper bumpers, like Rolls-Royce, Lamborghini I, Porsche Panam, er, an, etc.

Performance: Our bumper molds consistently deliver higher precision and quality in the molded parts compared to others.

Uniqueness:O ur bumper molds have unique features and innovations that set them apart. It includes advanced cooling systems, innovative design elements, and special coatings that improve durability and reduce cycle times.

Quality AssAssurancestressesss our commitment to quality assurance processes and standards that ensure the reliability and consistency of our bumper mold's output.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness