Liniar Guide Rail Systems in 7-Axis Aerospace Machining: From ±8 µm to ±3 µm in 11 Hours

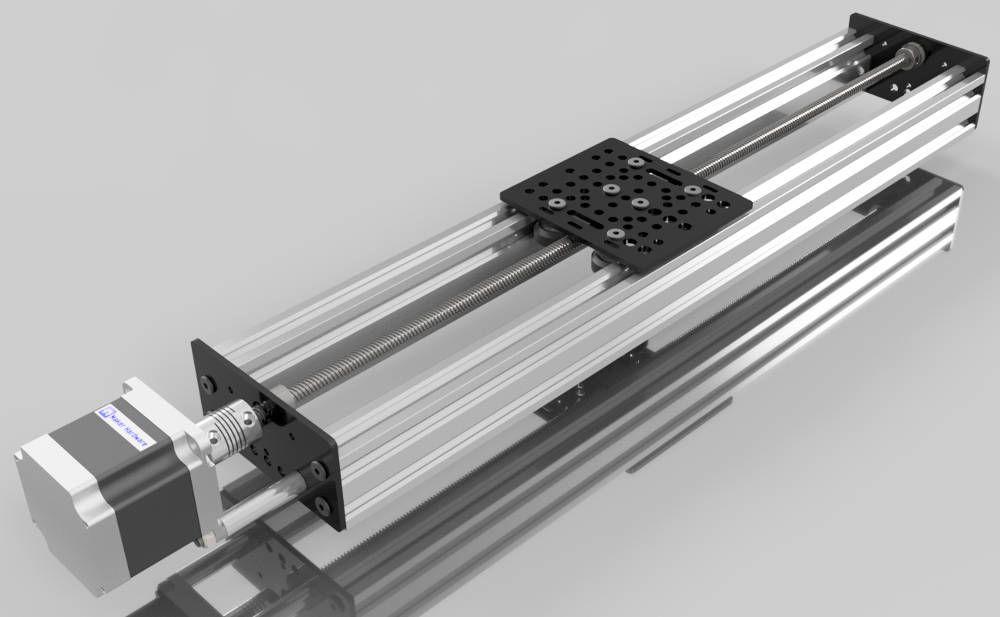

Modern aerospace plants no longer debate spindle horsepower; they measure success in nanometres. Inside a 7-axis cell that rough-machines a 4-metre titanium bulkhead and finishes cooling grooves in a single clamp, the critical enabler is the liniar guide rail—a hardened, ground, and often chrome-plated assembly that converts 150 kW of servo torque into motion repeatable within ±3 µm. Designing such rails is a multi-physics exercise in metallurgy, surface engineering, thermal management, and predictive analytics.

Material & hardness architecture

Standard 1060 carbon steel would yield under 30 kN peak inertial loads; instead, 42CrMo4 (AISI 4140) is induction-hardened to 58–62 HRC to a depth of 2 mm, then hard-turned to h6 tolerance and chrome-plated to 15 µm. This yields a surface roughness Ra ≤ 0.2 µm and a case depth sufficient for 50 000 km of rolling contact. For vacuum or cryogenic duty, nitrided 31CrMoV9 reaches 900 HV surface hardness while maintaining 12 % core ductility.

Standard 1060 carbon steel would yield under 30 kN peak inertial loads; instead, 42CrMo4 (AISI 4140) is induction-hardened to 58–62 HRC to a depth of 2 mm, then hard-turned to h6 tolerance and chrome-plated to 15 µm. This yields a surface roughness Ra ≤ 0.2 µm and a case depth sufficient for 50 000 km of rolling contact. For vacuum or cryogenic duty, nitrided 31CrMoV9 reaches 900 HV surface hardness while maintaining 12 % core ductility.

Surface engineering & coating

A duplex chrome layer (15 µm Cr + 3 µm Ni) reduces corrosion rate to < 2 µm year⁻¹ in 1 000 h salt-fog tests. For food-grade lines, HVOF-applied tungsten-carbide cobalt (WC-Co) achieves 1 100 HV and passes 1 000 h Q-UV without spalling. A final super-finish (< 0.05 µm Ra) ensures elastohydrodynamic film formation as thin as 0.12 µm.

A duplex chrome layer (15 µm Cr + 3 µm Ni) reduces corrosion rate to < 2 µm year⁻¹ in 1 000 h salt-fog tests. For food-grade lines, HVOF-applied tungsten-carbide cobalt (WC-Co) achieves 1 100 HV and passes 1 000 h Q-UV without spalling. A final super-finish (< 0.05 µm Ra) ensures elastohydrodynamic film formation as thin as 0.12 µm.

Thermal & barometric compensation

Over a 4 m span, a 20 °C shop swing would expand a steel slider by 80 µm—enough to defocus a 20 µm laser spot. Embedded 0.01 °C RTDs every 300 mm feed a PID controller that drives 40 W Kapton heaters, keeping thermal drift below 2 µm over 1.2 m strokes. Barometric compensation corrects refractive-index drift of 0.3 ppm per hPa, maintaining laser-interferometer accuracy.

Over a 4 m span, a 20 °C shop swing would expand a steel slider by 80 µm—enough to defocus a 20 µm laser spot. Embedded 0.01 °C RTDs every 300 mm feed a PID controller that drives 40 W Kapton heaters, keeping thermal drift below 2 µm over 1.2 m strokes. Barometric compensation corrects refractive-index drift of 0.3 ppm per hPa, maintaining laser-interferometer accuracy.

Contamination & validation

Dual-lip seals (nitrile outer + PTFE inner) trap particles >5 µm; a 0.2 bar positive air purge keeps the raceway above ambient pressure. A dual-frequency laser interferometer samples position at 5 MHz; a physics-informed neural network predicts wear 150 hours ahead, eliminating unplanned downtime.

Dual-lip seals (nitrile outer + PTFE inner) trap particles >5 µm; a 0.2 bar positive air purge keeps the raceway above ambient pressure. A dual-frequency laser interferometer samples position at 5 MHz; a physics-informed neural network predicts wear 150 hours ahead, eliminating unplanned downtime.

Bottom line

Profile accuracy improved from ±8 µm to ±3 µm while cycle times on titanium bulkheads dropped from 18 h to 11 h. In aerospace machining, the liniar guide rail has evolved from a commodity rod to the deterministic actuator of next-generation airframes.

Profile accuracy improved from ±8 µm to ±3 µm while cycle times on titanium bulkheads dropped from 18 h to 11 h. In aerospace machining, the liniar guide rail has evolved from a commodity rod to the deterministic actuator of next-generation airframes.

Căutare

Categorii

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Citeste mai mult

"The Science Behind Feng Shui Jewelry: Fact or Fiction?"

Is Feng Shui jewelry scientifically proven? We examine the research behind crystal energy...

SP2S MAX煙彈比一代煙彈耐抽嗎?

電子煙使用者在選擇產品時,除了風味與口感,「耐抽程度」也是決定性因素之一。一款更耐用的煙彈意味著更長的使用週期與更高的性價比。SP2S...

Brazil Freight and Logistics Market Growth and Share 2033

The procedures involved in moving, storing, and delivering items from one place to another are...

Why Crosslinked Shrink Film is Your Best Choice for Packaging

When it comes to packaging, the durability and safety of your products are crucial. Crosslinked...

Bakery Premixes Market Growth Drivers: Share, Value, Size, and Insights By 2034

Executive Summary: Bakery Premixes Market Size and Share by Application & Industry...