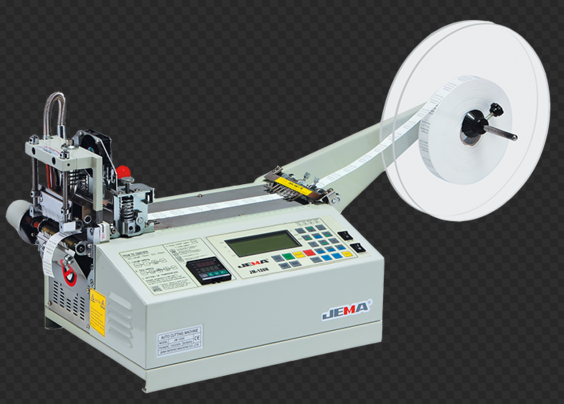

Shank Button Feeder Integration Improves Productivity, Reliability, and Product Consistency

A Shank Button Feeder is a specialized device designed to automate one of the most intricate steps in garment production: supplying shank buttons to sewing or attaching equipment. By minimizing manual handling, this technology addresses both efficiency and accuracy, two essential factors in large-scale apparel manufacturing. As global markets demand faster output and higher quality standards, the role of such feeders has become increasingly important for factories seeking to maintain competitiveness.

Importance in Garment Production

Shank buttons, which are distinguished by their protruding loop on the back, are commonly used in coats, jackets, and uniforms. Unlike flat buttons, they require careful alignment and handling to ensure proper placement during stitching. Manual feeding can be time-consuming and inconsistent, which may lead to variations in garment quality. Automated feeding devices simplify this task, ensuring each button is supplied consistently, thereby reducing the risk of production errors.

Enhancing Precision and Productivity

Accuracy in button placement is crucial for both the functionality and appearance of a garment. Feeding machines use controlled guiding mechanisms to deliver buttons directly to the attachment unit, synchronizing with sewing operations. This eliminates misalignment and ensures a uniform finish across all pieces in a production batch. Moreover, the increased speed of automated feeding significantly raises productivity, enabling manufacturers to meet tight deadlines without sacrificing quality.

Versatility and Adaptability

Modern feeders are designed with adaptability in mind, capable of handling a range of button sizes and styles. Adjustable trays and interchangeable parts allow for quick changeovers between different garment types, making them suitable for both large-scale and small-batch production. This versatility provides manufacturers with greater flexibility, especially in industries where fashion trends change rapidly and demand customized solutions.

Durability and Maintenance

Industrial equipment must withstand long hours of continuous operation. High-quality feeders are constructed with robust materials and precision-engineered components to ensure longevity. Routine maintenance, such as cleaning and occasional part replacement, keeps the machines in optimal condition. Many models also include diagnostic features that alert operators to irregularities, reducing unexpected downtime and improving overall efficiency on the production floor.

Economic and Labor Benefits

By automating repetitive feeding tasks, factories can reduce labor intensity while reallocating workers to more skilled roles. This not only improves job satisfaction but also enhances operational efficiency. While the upfront investment may seem substantial, the long-term savings achieved through reduced errors, consistent quality, and higher output often outweigh initial costs. For many garment manufacturers, adopting automated feeders represents a strategic step toward sustainable growth.

The introduction of button feeding automation has transformed how factories approach garment production. By combining precision, adaptability, and efficiency, shank button feeders help manufacturers achieve consistent quality while reducing labor strain and material waste. As the apparel industry continues to evolve, the role of automated solutions will remain central in meeting the demands of fast-paced markets and ensuring long-term competitiveness.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness