Durability and Precision: Why Linear Guides Are Essential in Heavy Industry

Heavy industry operates under extreme conditions. From steel manufacturing and mining to shipbuilding and energy production, machines are expected to handle massive loads, work continuously, and maintain accuracy despite heat, dust, and vibration. In such demanding environments, reliability is not optional—it is critical. This is where linear guides prove indispensable, combining durability with precision to keep heavy industry running smoothly.

The Challenge of Heavy Industry

Unlike light manufacturing, heavy industry involves equipment that faces constant stress. Components must support enormous weights and withstand shocks while still delivering accurate motion. Traditional sliding systems often fail under these conditions, leading to excessive wear, frequent breakdowns, and costly downtime. Linear guides solve this challenge by distributing loads evenly, minimizing friction, and ensuring consistent performance under extreme strain.

Why Precision Matters in Tough Environments

Precision may not be the first word that comes to mind when thinking about heavy industry, but it is just as important as strength. For example, in mining equipment, drilling rigs must follow exact paths to avoid costly errors. In steel production, cutting systems must move with accuracy to produce consistent results. Linear guides allow machines to perform these tasks reliably, maintaining high standards even in the harshest environments.

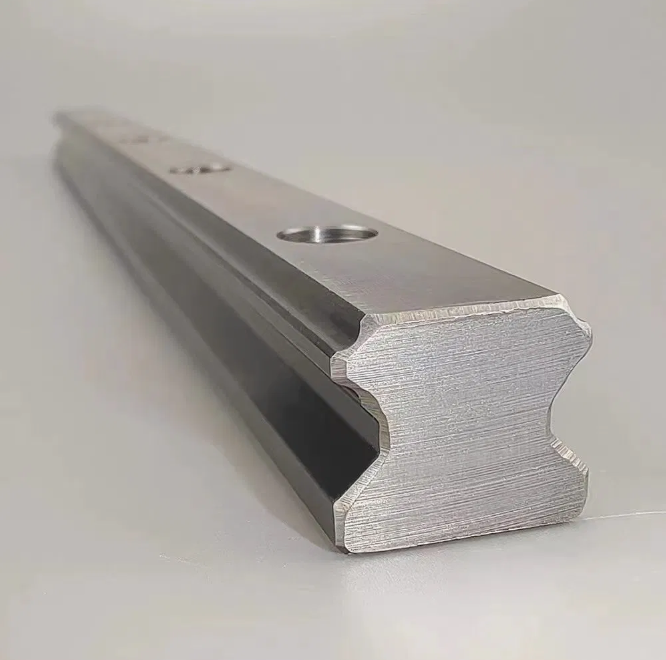

Built for Durability

Modern linear guides are engineered with advanced materials and surface treatments that increase resistance to corrosion, wear, and temperature changes. Specialized sealing systems protect against dust, dirt, and debris, ensuring long service life even when operating outdoors or in hostile industrial conditions.

These design innovations mean that linear guides require less maintenance while still delivering top-level performance. For industries where machines must operate 24/7, this durability is vital. Reduced downtime not only saves money but also increases overall productivity.

Applications in Heavy Industry

Linear guides find application across multiple heavy industrial sectors:

-

Mining: Supporting the motion of drilling, crushing, and transportation systems.

-

Steel manufacturing: Guiding precision cutting, pressing, and rolling machines.

-

Energy sector: Enabling smooth movement in turbines, generators, and renewable energy systems.

-

Shipbuilding: Assisting in the assembly and welding of massive ship components.

-

Construction machinery: Providing stable guidance in cranes, excavators, and tunneling equipment.

Each of these fields demands not only strength but also reliability and accuracy—qualities that linear guides consistently provide.

Reducing Costs Through Reliability

Heavy industry faces constant pressure to reduce operational costs while maximizing output. Unplanned downtime is one of the most expensive issues for any manufacturer. By integrating linear guides into critical machinery, companies can significantly cut maintenance requirements and extend the operational lifespan of equipment. This translates into fewer interruptions and greater cost efficiency over time.

Partnering With Experts

Manufacturers seeking to enhance their heavy-duty systems rely on trusted partners to provide high-quality motion solutions. Companies such as Yinhe Transmission specialize in developing linear guides that meet the toughest industrial requirements, ensuring both precision and durability. By choosing advanced motion components, businesses gain a competitive edge in terms of reliability, efficiency, and long-term savings.

The Road Ahead

As industries modernize and embrace digital transformation, the need for precise, durable motion components will only grow. Even in heavy-duty applications, accuracy is key to reducing waste, improving sustainability, and maintaining high standards of production. Linear guides will remain central to this evolution, bridging the gap between strength and precision.

Conclusion

Heavy industry cannot afford weak links in its production chain. Linear guides provide the strength, durability, and precision necessary to ensure reliable performance under the most extreme conditions. By working with trusted suppliers like Yinhe Transmission, companies can equip themselves with motion technology built to withstand heavy demands while delivering consistent results.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness