Ensuring Reliability and Efficiency: A Comprehensive Look at Industrial Power Distribution Systems

Industrial facilities rely on a stable and efficient power supply to operate machinery, equipment, and processes. Industrial power distribution systems are the backbone of this power supply, responsible for delivering electricity from the utility grid to various loads within the facility. A well-designed and maintained industrial power distribution system is crucial for minimizing downtime, improving productivity, and ensuring the safety of personnel. This article provides a comprehensive overview of industrial power distribution systems, exploring their key components, design considerations, and best practices for operation and maintenance.

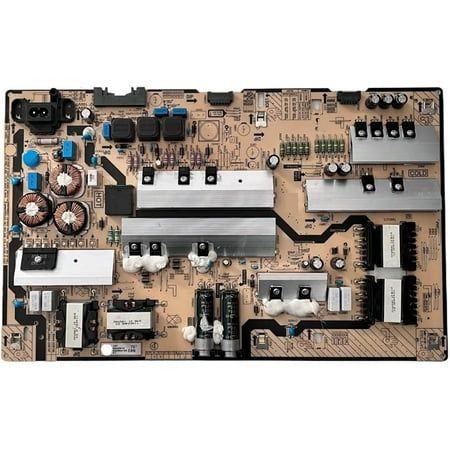

Key Components of Industrial Power Distribution Systems

Industrial power distribution systems typically consist of the following key components:

- Service Entrance: The point where the facility connects to the utility grid. This typically includes a main switchgear assembly with a circuit breaker or fused disconnect switch.

- Transformers: Transformers are used to step down the voltage from the utility voltage to the voltage levels required by the facility's equipment.

- Switchgear: Switchgear assemblies house circuit breakers, fuses, and other protective devices that protect the system from overloads, short circuits, and other faults.

- Panelboards: Panelboards distribute power to individual circuits within the facility.

- Motor Control Centers (MCCs): MCCs house motor starters, variable frequency drives (VFDs), and other control devices for motors.

- Cables and Conductors: Cables and conductors carry electricity throughout the system.

- Grounding System: The grounding system provides a path for fault currents to flow back to the source, protecting personnel and equipment from electrical shock.

- Power Quality Equipment: Power quality equipment such as harmonic filters and surge suppressors are used to improve the quality of the power supply.

Design Considerations for Industrial Power Distribution Systems

Designing an industrial power distribution system requires careful consideration of several factors:

- Load Requirements: The system must be designed to meet the facility's current and future load requirements. This includes determining the total power demand, the types of loads, and the voltage levels required.

- Reliability Requirements: The system must be designed to meet the facility's reliability requirements. This includes considering the consequences of power outages and the need for backup power systems.

- Safety Requirements: The system must be designed to meet all applicable safety codes and standards. This includes ensuring proper grounding, overcurrent protection, and arc flash protection.

Поиск

Категории

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Больше

Organic Pet Food Market to Reach USD 4.29 Billion by 2033, Growing at 7.2% CAGR

Organic Pet Food Market Overview

The global organic pet food market size was valued at USD...

Content Marketing Software Market Trends: Growth, Share, Value, Size, and Analysis By 2035

What’s Fueling Executive Summary Content ing Software Market Size and Share...

How to Achieve the Perfect Exhaust Sound: S55 Titanium Valved Catback Exhaust Explained

Nothing screams performance like the guttural roar of a finely tuned exhaust. For BMW...

Linear Bearings in Clean-Room Robotics: Why Sub-Class 1 ISO Performance Demands More

When a wafer-handling robot glides across a semiconductor clean-room, the linear bearings hidden...

Celiac Disease Market Value, Size, Analysis, Scope, Demand, Opportunities

"Executive Summary Celiac Disease Market :

Global celiac disease market size was...