How Precision Linear Rails Improve Efficiency in Robotics and Automation

Automation has become the heartbeat of modern industry. From car assembly plants to delicate surgical robots, automated systems are everywhere — making work faster, safer, and more efficient. But what many people overlook is the quiet, precise mechanism that makes it all possible: the linear rail.

Without linear rails, robotic arms wouldn’t move smoothly, precision equipment would vibrate, and industrial systems would lose their accuracy. These simple yet powerful components are the backbone of the automation revolution.

So, how exactly do precision linear rails enhance the efficiency of robotics and automation systems? Let’s take a closer look — from how they work, to what makes a high-quality rail system like YHLinear’s so essential.

Understanding Linear Rails in Simple Terms

Think of a linear rail as a track for movement — it allows a robot, tool head, or platform to glide smoothly back and forth in a straight line. The rail provides guidance and stability, while slider blocks (also called carriages) ride along the rail using ball bearings or rollers to minimize friction.

In robotics and automation, these rails make sure every motion is smooth, stable, and repeatable. Whether it’s a robotic arm welding parts or a pick-and-place machine positioning microchips, precision linear rails are what make accuracy possible.

They prevent wobbling, misalignment, and uneven movement — all of which could ruin a production process.

The Role of Linear Rails in Automation

Automation systems are all about repetition and reliability. Machines must repeat the same task thousands of times with consistent accuracy. If there’s even a slight deviation in positioning, it could cause product defects or system errors.

That’s why linear rails are indispensable in:

-

CNC machining centers

-

Robotic arms and cobots

-

Packaging and labeling equipment

-

Pick-and-place systems

-

3D printing and additive manufacturing

-

Medical automation systems

In each case, the linear rail acts as a precise guide — enabling smooth and exact motion, even under heavy loads or high speeds.

How Linear Rails Enhance Efficiency

The magic of linear rails lies in their ability to maintain precision while reducing friction and vibration. This combination directly boosts efficiency across several key areas:

1. Speed with Stability

Modern automation demands both high speed and accuracy. Poorly aligned systems create drag or vibration at high speeds.

Linear rails ensure that the moving platform stays stable and aligned, even when operating at top velocity. The result is faster cycle times and smoother workflows.

2. Reduced Maintenance Costs

Because linear rails distribute loads evenly and reduce metal-to-metal contact, wear and tear is minimal.

This means fewer breakdowns, lower maintenance costs, and longer system lifespans — all of which directly improve ROI.

3. Energy Efficiency

Reduced friction doesn’t just mean smoother motion — it also means lower energy consumption.

Robotic systems that use high-quality linear rails can operate efficiently with less power, making the overall operation more sustainable.

4. Consistent Accuracy

Whether a robot is placing a microchip or handling automotive parts, precision is everything.

Linear rails maintain consistent alignment over long working periods, minimizing error accumulation and improving product quality.

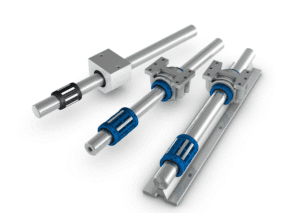

A Look Inside: The Design of a Linear Rail System

A typical linear rail system consists of:

-

A hardened steel rail – usually precision-ground for straightness.

-

A carriage or slider block – housing recirculating ball bearings or rollers.

-

End caps and seals – to keep contaminants out and retain lubrication.

Each of these parts works in harmony to ensure frictionless, linear movement.

Some systems, like those provided by https://yhlinear.com/, use specialized materials and heat treatments to increase durability and load capacity. The result is ultra-smooth motion that stays accurate even after millions of cycles.

The Relationship Between Robotics and Linear Motion

In robotics, motion control is everything. Robots depend on precise, repeatable positioning to perform complex tasks. Linear rails provide the physical foundation for that control.

For instance, in a 6-axis robotic arm, linear rails might control the movement of the entire base or guide the end effector for assembly tasks. In warehouse automation, linear rails help shuttle goods across conveyor systems with exact positioning.

When integrated properly, they reduce backlash (mechanical play) and absorb vibrations — ensuring every robotic movement is both fast and accurate.

This combination of speed, control, and predictability is what allows robots to outperform manual operations in both precision and consistency.

YHLinear: Precision You Can Count On

Choosing the right linear rail is not just about specifications — it’s about trust and quality.

That’s why engineers and manufacturers around the world rely on YHLinear, one of China’s leading specialists in linear motion systems.

YHLinear offers a full range of linear guide rails, blocks, and bearings that are designed for maximum stability, durability, and accuracy.

Every rail produced at https://yhlinear.com/ undergoes rigorous quality control and precision testing to ensure world-class performance.

Whether you’re building a robotic arm, an automated assembly line, or a precision measurement system, YHLinear has the expertise and product range to match your needs perfectly.

Common Challenges in Linear Motion and How to Solve Them

Even the best systems can face challenges — but understanding them helps prevent costly mistakes.

1. Contamination:

Dust or debris can affect smooth operation. Use proper seals and covers to protect rails.

2. Misalignment:

Improper installation can lead to uneven wear. Always ensure the rail and carriage are perfectly aligned.

3. Lubrication Issues:

Insufficient or excessive lubrication can shorten lifespan. Follow manufacturer recommendations for maintenance schedules.

4. Overloading:

Every rail has a maximum dynamic load capacity. Exceeding it can cause deformation or vibration. Choose a rail that suits your application load.

By addressing these factors early, engineers can achieve a long-lasting, efficient automation system.

Case Study: Robotics in Electronics Manufacturing

Let’s look at a real-world example.

In electronics manufacturing, precision is critical. Robotic systems assemble circuit boards, handle tiny components, and perform inspections at lightning speed.

Here, linear rails make all the difference.

A slight vibration or misalignment can cause a robot to misplace a component — leading to defective products.

By using high-precision linear rails, manufacturers achieve ultra-smooth motion and pinpoint accuracy.

The result? Faster production, fewer errors, and higher-quality products — exactly what’s needed in today’s competitive markets.

Future Trends: Smart Linear Systems

As automation enters the age of Industry 4.0, linear motion systems are becoming smarter.

Future rails will integrate sensors, IoT connectivity, and AI-based diagnostics to monitor performance in real time.

This allows for predictive maintenance, where systems can detect wear before it becomes a problem — reducing downtime and maximizing uptime.

Manufacturers like YHLinear are already exploring smart motion technologies that combine traditional mechanical precision with digital intelligence.

This evolution will redefine how automation systems operate — making them faster, smarter, and more reliable than ever.

The Bottom Line

Linear rails may look simple, but they’re the unsung heroes of automation.

They give robots their stability, accuracy, and smoothness, enabling the incredible precision that modern industries depend on.

Whether you’re designing a new robotic system or optimizing an existing automation line, investing in high-quality linear motion components is the smartest move you can make.

For durable, high-precision, and custom-engineered solutions, YHLinear continues to lead the way — helping engineers build smoother, faster, and smarter machines every day.

You can learn more or explore their advanced product range at https://yhlinear.com/.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness