The Importance of Choosing the Right Fabric for Inflatable Boats

Inflatable boats are favored for their portability, ease of storage, and versatility on the water. However, the quality of the material used in their construction is paramount to their performance and durability. Inflatable Boat Fabric Manufacturers play a crucial role in providing high-quality materials designed to withstand the demands of both recreational and commercial boating. These specialized fabrics, often made from durable PVC or Hypalon (CSM), offer a balance of strength, flexibility, and resistance to environmental elements, ensuring inflatable boats remain reliable and safe in all conditions.

The Benefits of High-Quality Inflatable Boat Fabric

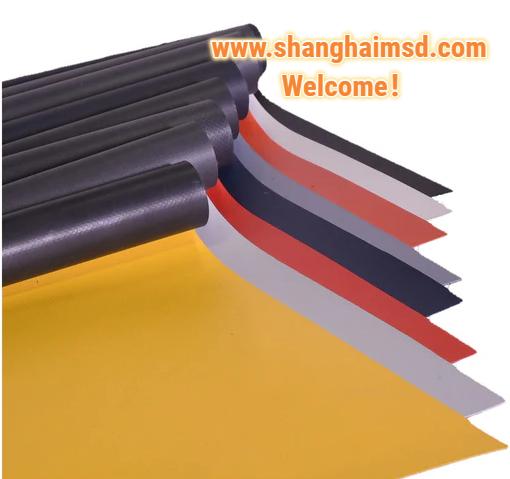

The key to a great inflatable boat lies in the fabric used for its construction. Inflatable Boat Fabric Manufacturers produce materials that are not only lightweight but also resistant to UV rays, chemicals, and abrasions. These fabrics are engineered to withstand rough handling, exposure to harsh weather conditions, and contact with saltwater. PVC, commonly used in consumer-grade inflatable boats, is a cost-effective material known for its waterproof and airtight qualities. It offers flexibility, ease of maintenance, and resilience against environmental elements.

On the other hand, Hypalon (CSM) is favored for its superior strength and resistance to extreme temperatures, oil, and fuel. This material is typically used in military-grade and commercial inflatable boats due to its high performance under demanding conditions. The fabric’s ability to endure heavy usage and exposure to extreme conditions makes it a preferred choice for boats that require additional durability and resistance to wear and tear.

Coatings and Treatments for Enhanced Durability

One of the most important aspects of inflatable boat fabric is the coatings applied during production. Inflatable Boat Fabric Manufacturers often treat the fabric with UV-resistant coatings, ensuring that the material remains durable even after prolonged exposure to sunlight. These coatings help prevent degradation and discoloration, maintaining the boat’s aesthetic and structural integrity over time.

In addition, anti-fungal and anti-bacterial treatments are commonly applied to inflatable boat fabrics to prevent mold and mildew growth. This is particularly important for boats stored in humid or wet environments, where mold can degrade the fabric and affect the boat’s performance. These coatings enhance the fabric’s resistance to marine organisms, ensuring a longer lifespan and easier maintenance.

In conclusion, Inflatable Boat Fabric Manufacturers are essential in delivering the high-quality materials needed for inflatable boats to perform well and last longer. Whether you are looking for a lightweight, cost-effective option or a more robust, heavy-duty fabric, choosing the right manufacturer is key to ensuring the boat’s durability, safety, and performance. For top-quality inflatable boat fabrics, visit shanghaimsd.com today.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness