In CNC machining, achieving precise and reliable positioning of workpieces is critical for meeting technical requirements. This often necessitates the use of specialized fixtures designed to securely hold workpieces in place based on their structure, machining method, and production volume. This article explores the role of specialized fixtures in enhancing machining accuracy, efficiency, and safety.

Understanding the Role of Specialized Fixtures in CNC Machining

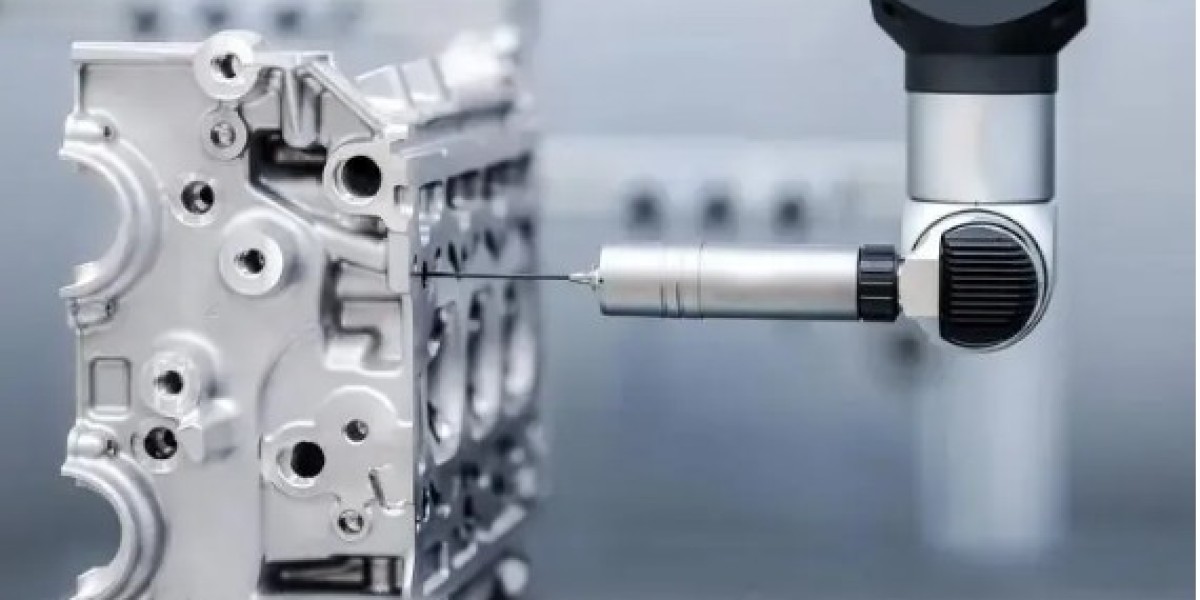

In the realm of CNC machining, the use of fixtures is crucial for ensuring that workpieces are accurately and securely positioned during processing. These devices, known as "machine fixtures," are designed to hold workpieces in place and determine their relative position to the cutting tools.

Types of Fixtures

Machine fixtures are primarily used for securing workpieces, whereas devices that hold various cutting tools are generally referred to as "auxiliary tools." Sometimes, auxiliary tools are considered part of the machine fixture system. Fixtures can be broadly categorized into three types: universal fixtures, specialized fixtures, and adjustable fixtures.

Introduction to Specialized Fixtures

Specialized fixtures are custom-designed and manufactured to meet the specific requirements of particular workpieces or machining processes. They offer several key advantages:

Precision in Workpiece Surface Processing: Specialized fixtures ensure high accuracy in dimensions, parallelism, and concentricity of workpiece surfaces. For complex structures with stringent positional tolerances, universal fixtures may not suffice, making specialized fixtures essential for meeting these precision requirements.

Reduced Processing Time and Increased Efficiency: The time required for a machining operation includes both the actual machining time and the auxiliary time for loading and unloading workpieces. Specialized fixtures streamline the setup and replacement of workpieces, eliminating steps like alignment and marking. This reduction in auxiliary time leads to improved productivity. Multi-station fixtures enable simultaneous processing of multiple workpieces, effectively reducing the setup time to match that of processing a single piece. Furthermore, rotating multi-station fixtures allow for overlapping auxiliary and machining times by enabling the loading and unloading of workpieces while another is being machined. Overall, the use and continuous improvement of specialized fixtures significantly shorten process cycles and address increasing production demands.

Enhanced Machine Tool Capability: By installing boring fixture kits on standard lathes, one can achieve the functionality of a boring mill. Specialized fixtures also enable the processing of complex shapes, thereby maximizing the potential of general-purpose machine tools.

Reduced Labor Intensity and Improved Safety: Pneumatic, hydraulic, and highly automated specialized fixtures can significantly reduce worker fatigue, ensure safety, and enhance product quality and production efficiency. For instance, when machining large workpieces that require multiple flips, such as screw holes on the underside of a bed, the use of electric rotating fixtures can boost productivity, reduce labor intensity, and ensure safer operations.

Despite their crucial role in manufacturing, specialized fixtures are not always necessary. When deciding to use a specialized fixture, factors such as production cost, cycle time, and product requirements must be considered. In some cases, standardized universal fixtures or alternative manufacturing strategies might be more appropriate. Therefore, a thorough assessment of specific production needs and scenarios is essential when determining whether to design and employ specialized fixtures.