Understanding the materials used in mechanical components is essential for ensuring their performance and longevity. This article categorizes these materials into metals and non-metals, discussing their properties and applications, and offering my perspective on the selection process.

Mechanical components are typically categorized based on their physical and chemical properties as well as their intended applications, which can be divided into two main categories: metal and non-metal materials. In my view, understanding these distinctions is crucial for engineers and designers alike.

I. Metal Materials

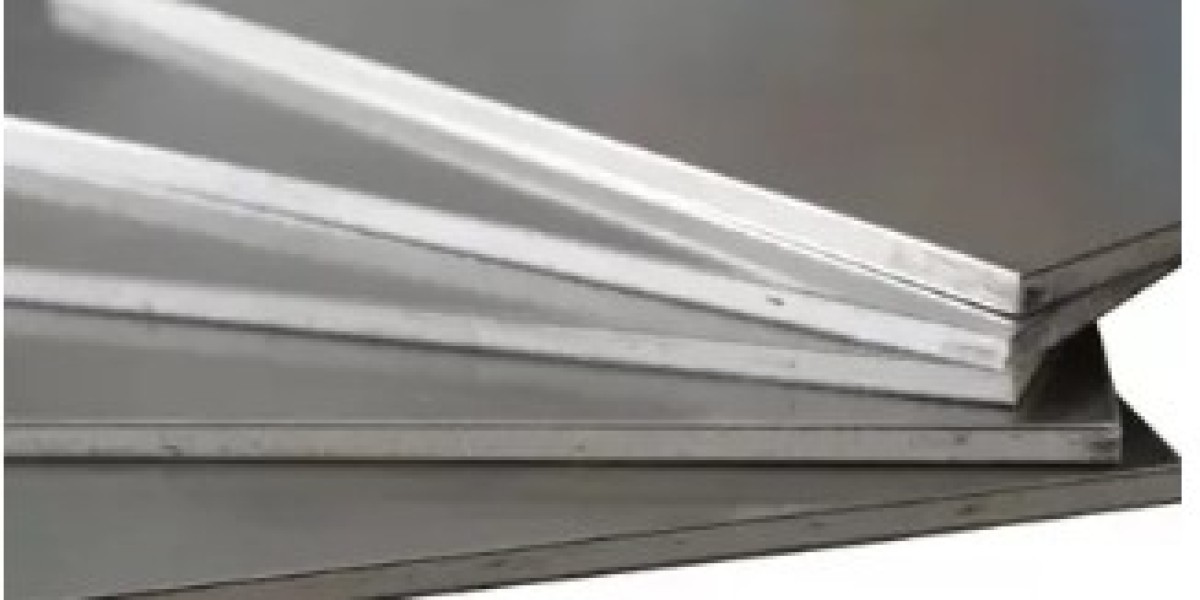

Steel Materials

Carbon Steel

- Properties: The strength and hardness of carbon steel increase with carbon content, though this often comes at the expense of plasticity and toughness. While it exhibits good thermal conductivity, its corrosion resistance is relatively poor.

- Applications:

- Low Carbon Steel: Suitable for parts requiring good plasticity, such as bolts, nuts, and automotive bodies.

- Medium Carbon Steel: Utilized in high-strength components like shafts and gears.

- High Carbon Steel: Ideal for high-hardness applications, such as cutting tools and molds.

Alloy Steel

- Properties: The addition of alloying elements like chromium and nickel significantly enhances strength and corrosion resistance.

- Applications:

- Low Alloy Steel: Commonly used in bridge and structural applications.

- High Alloy Steel: Employed in parts designed for high temperatures and corrosive environments, such as stainless steel tools and bearings.

Stainless Steel

- Properties: Known for its excellent corrosion resistance along with high strength and toughness.

- Applications:

- Austenitic Stainless Steel: Widely used in food processing and medical devices.

- Martensitic Stainless Steel: Appropriate for making knives and valves.

- Ferritic Stainless Steel: Often found in automotive exhaust systems.

Non-Ferrous Metals

Aluminum Alloys

- Properties: These alloys are lightweight yet strong, with excellent corrosion resistance and good thermal and electrical conductivity.

- Applications: Commonly used in aerospace, automotive manufacturing, and construction, such as aircraft components and window frames.

Copper Alloys

- Properties: Renowned for their superior electrical and thermal conductivity, coupled with good mechanical properties.

- Applications:

- Brass: Used in plumbing fittings and condensers.

- Bronze: Suitable for making bearings and gears.

- Nickel Silver: Commonly used in resistors and chemical equipment.

Titanium Alloys

- Properties: Characterized by high strength and low weight, along with excellent corrosion and heat resistance.

- Applications: Utilized in aerospace applications and medical devices, including engine components and prosthetic joints.

II. Non-Metal Materials

Polymeric Materials

Engineering Plastics

- Properties: Lightweight, corrosion-resistant, and exhibiting excellent electrical insulation.

- Applications:

- Polyamide (Nylon): Used for gears and bearings.

- Polyoxymethylene (POM): Ideal for precision components.

- Polycarbonate (PC): Employed in transparent parts and safety helmets.

Composite Materials

- Properties: Combining matrix and reinforcement materials, these exhibit outstanding mechanical properties.

- Applications:

- Glass Fiber Reinforced Plastic (GFRP): Used in marine vessels and construction.

- Carbon Fiber Reinforced Plastic (CFRP): Suitable for aerospace and racing applications.

Ceramic Materials

- Properties: High hardness, excellent wear and high-temperature resistance, although they are brittle.

- Applications: Used for cutting tools and high-temperature components, such as blades and turbine components.

Rubber Materials

- Properties: Known for their elasticity, good wear resistance, and insulation properties.

- Applications: Commonly found in seals and shock absorbers.

III. Principles of Material Selection

When selecting materials, I consider several key factors:

– Operating Conditions: Evaluating temperature, pressure, and corrosive environments to choose the most suitable material.

– Mechanical Properties: Ensuring the selected material possesses adequate strength, toughness, and durability.

– Machinability: Opting for materials that are easy to process.

– Economic Viability: Balancing cost with availability.

– Environmental Considerations: Assessing recyclability and environmental impact.

In summary, the selection of materials for mechanical components requires a comprehensive understanding of their physical and chemical properties, application requirements, and economic considerations. This holistic approach ensures the optimal performance and longevity of the components in their respective environments.