Introduction to Aluminum Die Casting

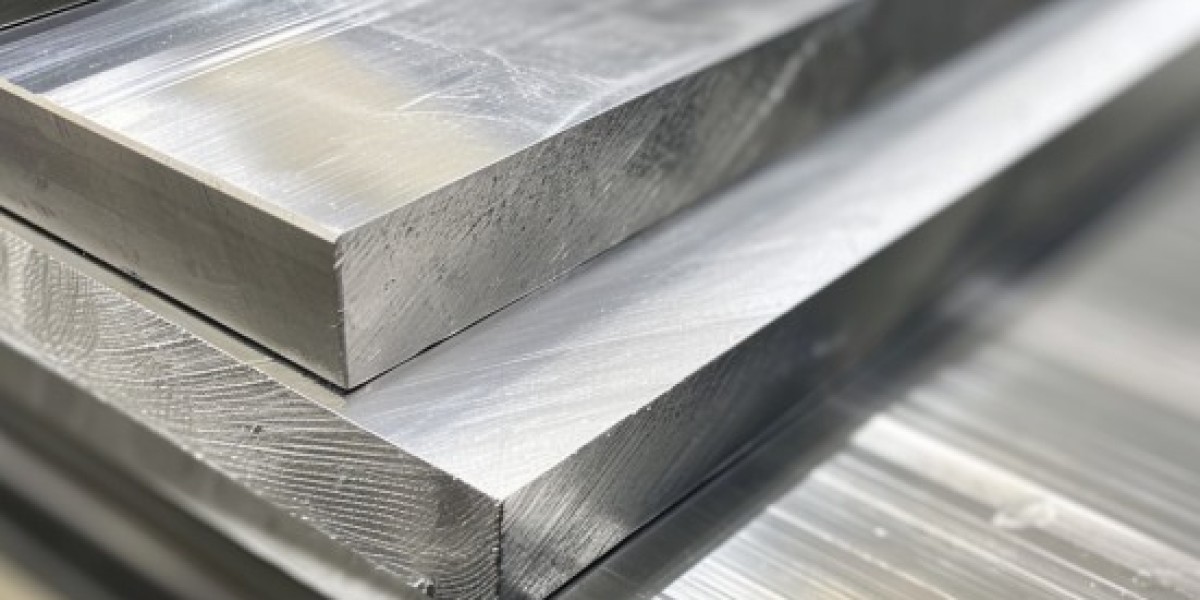

Aluminum die casting is a metal forming process widely used for mass production of components demanding precision attributes. As a prominent die casting manufacturer, Junying offers comprehensive aluminum die casting solutions tailored to clients' project requirements.

Aluminum Die Casting Methodology

The process involves injecting molten aluminum alloys at high pressures into reusable steel dies. Commonly used aluminum grades include A380, ADC12 and 319 exhibiting qualities like castability, strength and corrosion resistance.

Key factors are die design, injection pressure levels and cooling rates which influence process parameters and cycle times. Computer aided controls automate casting cycles enhancing outputs.

Aluminum Die Casting Services at Junying

Leveraging over 15 years experience, Junying owns state-of-the-art cold chamber machines with clamping forces up to 300 tons. In-house tooling capabilities aid quick prototyping.

As an integrated manufacturer, Junying offers value-added fabrication, assembly and surface treatment services facilitating one-stop project handling.

Advantages of Aluminum Die Casting

- Dimensional Accuracy

- Surface Finish

- Production Scalability

- Material Properties

- Cost Effectiveness

Applications

Aluminum die casting fulfills needs across industries like electronics, automotive, industrial machinery through attributes:

- Appliances

- Infrastructure

- Automotive

- Electronics

- Hardware

Service Capabilities at Junying

Junying caters project requirements from conceptualization to delivery through:

- Consultancy on specifications, volumes, schedules

- In-house tooling design and manufacturing

- Automated casting lines

- Value-added fabrication, coating services

- Quality protocols and certifications

Conclusion

In summary, aluminum die casting has become a favored technique meeting industry needs. As a capable outsourcing specialist, Junying consistently delivers high-quality cast components as per client expectations.